There are very few universal rules in the world. One rule that comes close is that you should always take it slow and easy when making the first cut in any material using any tool. The importance of this rule is obvious if you are cutting steel rods with a hacksaw or starting a drill bit in stainless steel plate. The importance of this rule may seem less noticeable if you are running wood through a table saw or making the first pass with a router bit. However, it is also equally true in much less obvious applications.

What is the first cut?

What is the first cut? That is a question that has puzzled humans for centuries. The answer may seem simple, but the answer is actually quite complex. In general, the first cut is the most superficial of cuts made when sawing or cutting something. It’s also known as a “primary” cut because it’s the first in a series of cuts that are made to create a particular object or piece of furniture.

The first cut can also be important from a safety standpoint. If you’re planning to make several cuts with your saw, you’ll want to make sure that your initial cut is precisely placed so that you don’t end up injuring yourself or damaging your equipment. Furthermore, if you’re working with wood that’s particularly dense or hard-to-cut, making an initial clean and accurate cut can save you hours of labor later on.

How to Make the First Cut

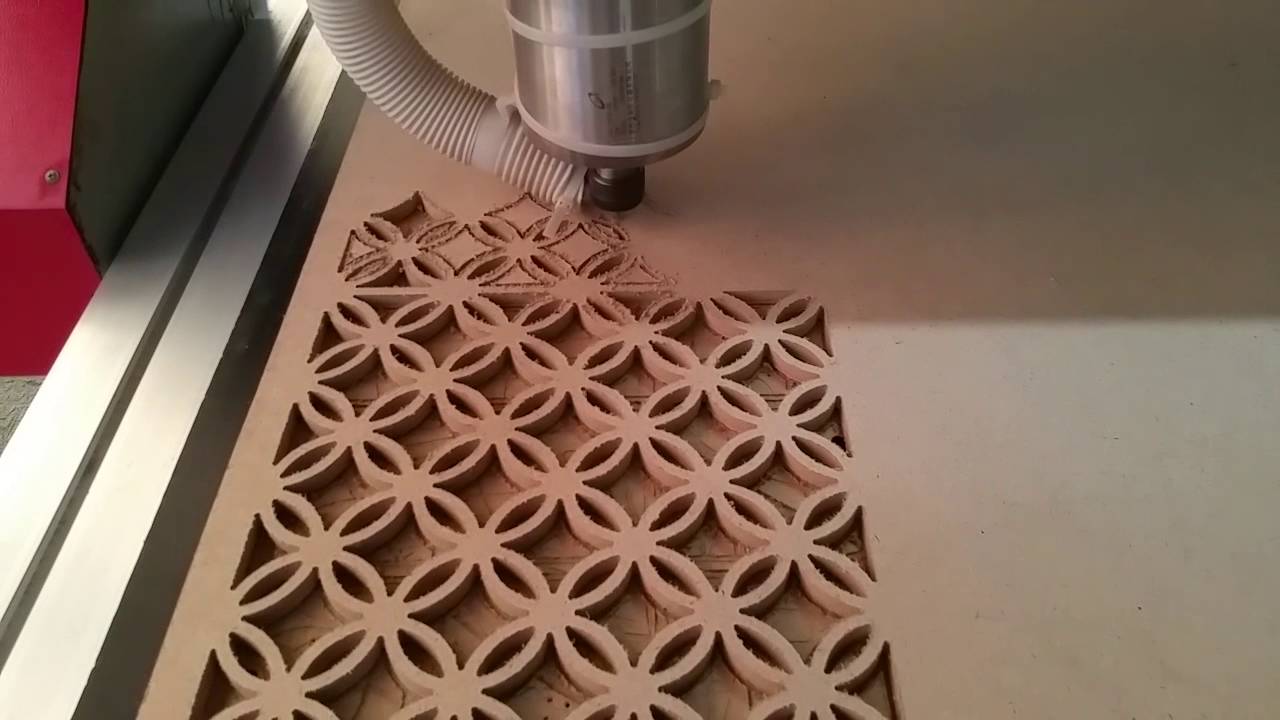

When cutting MDF with a CNC router and a diamond router bit, the true professional will very carefully test the setup with some slow passes to ensure the programming, the fixturing, and the tool are all correct. Even a highly non-obvious operation such as using EDM to cut carbide blanks to shape is much more likely to be successful if there is a couple, or at least one, slow pass to start. Making the first pass slowly allows you to test the design and security of the fixturing of the part without inviting catastrophe.

A slow first pass provides fine micro-honing of the tool before it begins the serious work. With a hacksaw on the steel rod or the drill bit on the stainless steel plate, it is very obvious that you need to start slowly since the tool will slip and skate over the surface of the metal otherwise. However, once you have cut a small hole in the plate, you can supply much more speed and pressure, knowing that the cutting edge will remain where it should. The same holds with more sophisticated applications such as the diamond router bit or the EDM. But, again, getting the cut started properly means a much better cut with cleaner edges and a much longer tool life.

Argument

The first cut is the most important step in any project. It determines how much work gets done and how successful the project will be. With a well-executed first cut, projects can move forward smoothly and on time, while minimizing wasted time and resources.

A well-executed project starts with a careful first cut. This step determines how much work gets done and how successful the project will be. To make the best decision, always use data to guide your choices. By using objective information, you can make informed decisions that lead to successful outcomes. A well executed first cut can save time and money on a project. Reduce the amount of rework that needs to be done by choosing the right tool for the job. By identifying where your effort is best spent, you will create a more effective plan that leads to success.

Fact

The first cut is the most important cut. It’s the first step in any project and it sets the tone for the rest of the job. If you’re not careful, your first cut can ruin your whole project. Here are six facts about first cuts that will help you stay on track:

- A good first cut eliminates unnecessary work. If you don’t eliminate anything from your initial plan, you’ll end up with a lot of extra work later on. You won’t have time to fix mistakes, and the finished product will be disappointing. Skipping a good first cut can lead to major problems down the road.

- A bad first cut leads to wasted time and money.

- A first cut ensures that the product is of a sufficient quality and meets all requirements.

- A first cut can often be the difference between success and failure. By making sure that all necessary steps have been taken, you can avoid potential problems later on down the line.

- First cuts are often made during early stages of development, when it is easier to determine whether a product is feasible or not.

- The first cut can also be used as a basis for future cuts, which will further improve the quality of the final product.

A first cut can be difficult, but it is essential if you want to produce high-quality products that meet customer expectations.

The Importance of a Good First Cut

In any business, the first cut is essential to success. A good first cut can save time, money, and resources by targeting the most important tasks and eliminating those that are not necessary. It can also help prevent potential problems and improve overall efficiency.

When making a first cut, it is important to consider the following factors: 1) what is the goal of the project? 2) what are the resources available? 3) who will be affected by the decision? 4) what is the timeline for completion? 5) what are some alternatives to consider? Once these questions have been answered, it is possible to make a more informed decision about which tasks should be tackled first. By taking this approach, businesses can ensure that their goals are met as quickly and efficiently as possible while minimizing potential complications down the road.

Conclusion:

In conclusion, the first cut is the most important when it comes to landscaping. It’s the start of the process, and if it’s done correctly, the rest of the work will fall into place. Get your first cut right, and you’ll be on your way to a beautiful landscape that’s both functional and pleasing to look at.